|

Back to start |

There was a great deal of other preparatory work to be done. Electricity and water had both to be brought to the site, electricity for a Kango hammer and water both for constant use during construction and later on for filling the pool. The local Water Board would consent to nothing larger than a 1 in. inlet, which meant that the pool would take a whole week to fill; but with the recirculation system of filtration to be installed, one fill would last indefinitely. Not only had some necessary water to be brought to the spot, some unnecessary water had to be got rid of, and the disposal of surface water which collected during construction presented awkward problems for months on end.

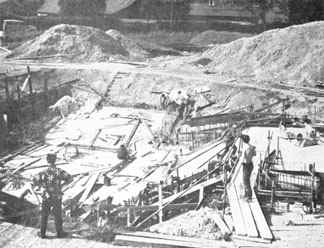

Other off-site preparations included the bending of the steel reinforcing rods, the stripping of the ex-railway trough wood of rusty nails and screws, and the preparing of the wood for rough shuttering - for although Wimpey's metal form work was to be used for the walls of the pool, strong barricades of wood would be needed to prevent landslides of the heavy clay surrounding the hole. On-site preparations would begin with marking out the hole to be excavated, the mechanical digging of the channels for the main sewer and the storm water drains (an outside firm asked £337 for this job alone), the mechanical excavation of the hole and its subsequent trimming to the exact dimensions needed, and the putting down, over the entire floor of the hole, of a "blinding layer" of weak concrete to give a clean working surface for the floor of the pool.

|

July 1962. |

| Back to previous. | Continue to next page. |

| Back to start | |